INTRODUCTION

The future of aviation is poised for a revolutionary shift with the development of hydrogen-powered airplanes designed to drastically reduce carbon emissions and promote sustainable air travel. These aircraft will utilize hydrogen fuel cells or hydrogen combustion engines as their primary energy source, replacing conventional jet fuel with clean-burning hydrogen.

The design incorporates lightweight materials and advanced aerodynamics to maximize efficiency and range. Hydrogen storage will be a key feature, with cryogenic tanks integrated into the airframe to safely store liquid hydrogen at ultra-low temperatures, ensuring sufficient fuel capacity for longer flights. The propulsion system, powered by electric motors fed by hydrogen fuel cells, will offer quieter operation with zero carbon emissions, significantly reducing the environmental impact of air travel.

Additionally, these airplanes will be equipped with state-of-the-art safety systems and optimized thermal management to handle the unique challenges of hydrogen fuel. By combining innovative engineering with hydrogen technology, future aircraft will enable airlines to meet stringent environmental regulations while maintaining performance and passenger comfort, ushering in a new era of eco-friendly aviation.

C1 DYNAMIC ROD SEAL

Rod seal for hydraulic and pneumatic cylinders, single-acting, rubber u-cup design.

PTFE SLIPPER SEAL®

Rotary seal for rotary distributors. Dynamic function on inner diameter. Double-acting, PTFE slipper seal design. Low friction. For high-pressure applications.

ELASTOMER O-RINGS

O-rings are circular sealing elements with circular cross-sections, and are mainly used in static applications. The sizes are specified by the inside diameter and the cross section diameter. Our O-rings are manufactured according to metric and imperial international standards such as AS 568B, DIN ISO 3601 and JIS.

Custom sizes of almost any dimension are possible, such as miniature O-rings, special O-rings with large dimensions and continuously molded and spliced cord. We utilize O-Ring compounds formulated to meet the most stringent industry standards, including FDA, USP, KTW, DVGW, BAM, WRAS (WRC), NSF, Underwriters Laboratories (UL), Aerospace (AMS) and many customer-specific requirements.

WARP SEALS

Warp Seals are special static seals that compensate for axial, radial and/or angular misalignment within a wide tolerance range. They are suitable, for example, for sealing port connections and feedthroughs of all kinds in housings.

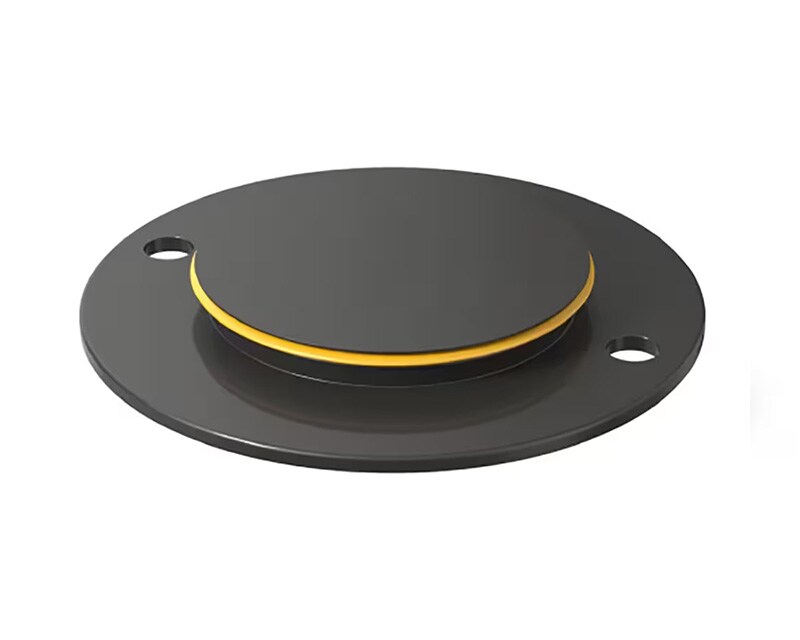

VENT VALVE FOR EV BATTERIES, CLIPHVENT

Parker CliPHvent battery vent valves protect EV battery housings against mechanical damage that may occur in case of pressure differences between the interior of the housing and the environment. They also seal against external liquids and dirt.

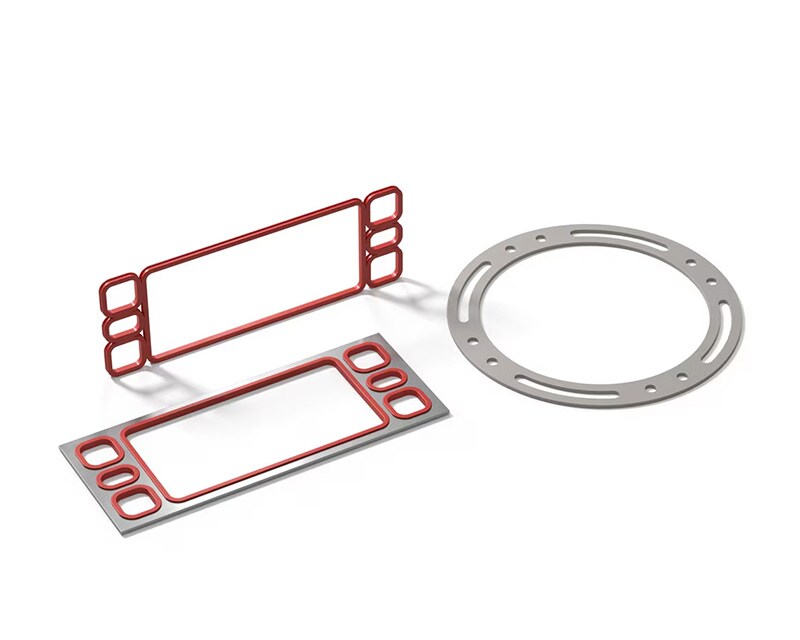

SEALS FOR BIPOLAR PLATES

Seals for bipolar plates provide reliable sealing for stacks in fuel cells and electrolyzers against the media required for operating fuel cells or electrolyzer cells. They prevent gas or electrolyte loss and ensure the performance of the total system.

ROLL2SEAL® BORE SEAL CAP

Self-retaining bore seal cap for the easy and reliable closure of bores.