HYDROGEN FUEL CELL VEHICLE

The world is currently pursuing all possible means to reduce global warming emissions from carbon-producing fuels. Hydrogen plays a critical role in creating alternative systems that provide the carbon-free energy required for a sustainable future

The transportation market has accelerated its transition from fossil fuels towards zero emission, renewable fuels. In the “heavy” transportation segment where battery powered electric vehicles can’t fully accommodate the market, the fuel cell electric powertrain is an ideal solution.

The hydrogen fuel cell system

A proton exchange membrane fuel cell (PEMFC) system brings several challenges with it since it requires a high-level cleanliness for both the hydrogen and air streams. Parker can support OEMs in their development, with its wide range of products that will purify and condition the gases and liquids in the system, leading to a longer life and higher performance.

Solutions for hydrogen fuel cell:

- Ion exchange filters for hydrogen fuel cells

- Fuel cell stack cooling

- Cathode air filters for hydrogen fuel cells

- Humidifier for hydrogen fuel cells

- Cathode water separators for hydrogen fuel cells

- Anode water separators for hydrogen fuel cells

- Hydrogen filter for hydrogen fuel cells

- Fuel delivery to hydrogen fuel cells

- Fuel conveyance for hydrogen fuel tank systems

- Sealing technology for hydrogen fuel cells

ION EXCHANGE FILTERS FOR HYDROGEN FUEL CELLS

The fuell cell stack is sensitive to electric short circuits, therefore, the conductivity of the coolant needs to be controlled.

Parker Ion Exchange Filters reduce the conductivity level of coolant to optimal levels, protecting and extending the life of the fuel cell.

Features and benefits:

• Ion exchange beads developed for fuel cell applications

• Filter performance optimized to the application

• Flexible port and mounting positioning

• Replaceable service element

Specifications:

• Flow rate: 10 LPM

• Capacity: 100 meq (anion + cation)

• Electrical conductivity: >5 µs / cm

FUEL CELL STACK COOLING

In fuel cell stacks coolers are used to maintain a stable operating temperature and prevent overheating of the fuel cell reaction, thereby maintaining a safe and stable operating temperature in a small tolerance field.

Parker’s QDC Quiet Air Oil Cooler with DC Motor and Quiet Air Oil Cooler with AC Motor remove excess heat from the fuel cell stack by circulating a coolant through a heat exchanger, which is in contact with the fuel cell stack. The coolant absorbs the excess heat and carries it away from the fuel cell stack, thereby maintaining a safe and stable operating temperature.

These coolers have the technical structure and the manufacturing process used (vacuum soldering) and subsequent rinsing of the parts in contact with the liquid increases reliability and reduces the risk of increased conductivity in the cooling liquid.

Related products:

CATHODE AIR FILTERS FOR HYDROGEN FUEL CELLS

The fuel cell cathode is very sensitive to impurities and gasses that can choke and permanently deteriorate the fuel cell stack.

Parker Cathode Air Filters will remove particles and harmful gasses from the air stream protecting and extending the life of the fuel cell.

Features and benefits:

• Customized solution for your needs

• Global R&D media development and optimisation

Specifications:

• Flow rate: 2 – 6 m3 / min

• Particle removal: up to 99% @ 2.5 pm

• Gas removal: NOx, SOx, Ammonia

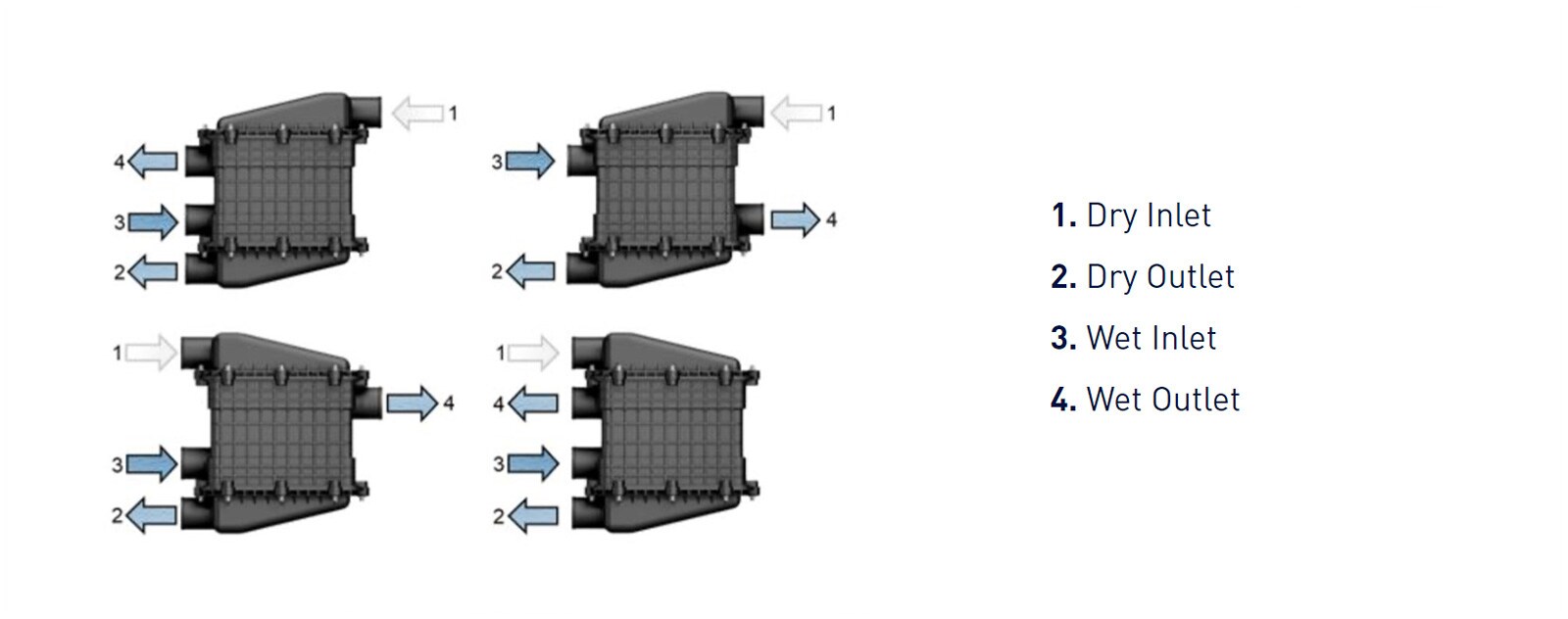

HUMIDIFIER FOR HYDROGEN FUEL CELLS

The proton exchange membrane needs to be kept humid to achieve maximum performance and extend the life of the fuel cell.

The Parker Humidifier will ensure the optimal level of humidity throughout the lifetime of the product.

Features and benefits:

• Proprietary technology delivers extended durability

• High resistance to chemical and thermal degradation

• Flexible port positioning

Specifications:

• Flow rate: 10,000 LPM

• Fluid temperature: -40 – 95°C

• Maximum pressure: 3 bar

CATHODE WATER SEPARATORS FOR HYDROGEN FUEL CELLS

During operation the fuel cell generates a significant amount of water on both the air and hydrogen side that needs to be removed. The water generated on the cathode exhaust needs to be separated from the air to protect the compressor.

Parker Cathode Water Separator will remove the water from the air exhaust thus protecting the compressor and extending its life.

Features and benefits:

• High efficiency water separation

• Low pressure drop

• Mechanical separator with high durability

• Modular design for different flow rates

Specifications:

• Flow rate: 2,000 – 10,000 sLPM

• Fluid Temperature: -40°C – 95°C

• Efficiency: up to 99%

ANODE WATER SEPARATORS FOR HYDROGEN FUEL CELLS

During operation the fuel cell generates a significant amount of water on both the air and hydrogen side that needs to be removed. The water generated on the anode side needs to be separated from the hydrogen return loop so that it is not recirculated into the fuel cell where it can flood the gas diffusion layer and negatively impact the performance of the stack.

Parker Anode Water Separator will remove the water from the hydrogen recirculation loop thus protecting the fuel cell and improving the performance.

Features and benefits:

• High efficiency water separation

• Low pressure drop

• Mechanical separator with high durability

• Modular design for different flow rates

Specifications:

• Flow rate: 1,000 – 5,000 sLPM

• Efficiency: up to 99%

• Automatic solenoid drain system

HYDROGEN FILTER FOR HYDROGEN FUEL CELLS

The fuel cell anode is very sensitive to impurities, thus a high-level purity hydrogen is required so as not to deteriorate the cell stack.

Parker H2 Filters remove particles and coalesce liquids from the H2 stream and can be used as a safety measure to protect the system.

Features and benefits:

• Coalescing and particle retention filtration

• Wide range of filtration types

Specifications:

• Filtration efficiency: 99% @ 3 microns

• Working pressure: Rated to 55 bar

• Material: Stainless steel

FUEL DELIVERY TO HYDROGEN FUEL CELLS

Heated hose solutions

Designed for heating and conveying media such as water to keep purge lines on fuel cells from freezing, Parker’s 14.5 mm O.D. heated hoses are uniquely made with both an extruded sheath and an overmold for protection and it helps to prevent blockages and maintain optimal performance by keeping the fuel system free from condensation buildup.

Parker’s Parflex SCR hoses lock-in the heating elements with an extruded sheath for added protection and long-lasting uniform heating. With pressures up to 10 bar (145 psi, 1MPa) the heated hoses with PA inner tube are chemically compatible for use with Hydrogen at temperatures from -40°C to 120°C (-40°F to 248°F). The overmold on the fittings provide impact and water resistance, making the hoses suitable for multiple environments.

Featured fittings

Parker supplies connectors for low-pressure systems that deliver hydrogen to the fuel cell. These products are compact and designed for leak-free media integration in fuel cell systems.

Related products:

FUEL CONVEYANCE FOR HYDROGEN FUEL TANK SYSTEMS

The use of fuel conveyance technology in hydrogen tank systems

Fuel conveyance products on hydrogen fuel tanks for trucks refer to the components that are used to store and transport Hydrogen fuel from the tank to the engine. Parker technology is used to connect, control the flow and to transfer hydrogen between different parts of the hydrogen fuel system, and are manufactured to meet the high pressure and extreme temperature requirements associated with hydrogen tank systems.

Featured fittings, connectors, regulators, valves, sensors and hose products

Parker can supply EC-79 fittings, valves, regulators, piping, pressure relief valves and sensors in a range of sizes, pressures, and temperatures. are critical, especially in demanding, corrosive, pressured and heat-intensive environments. All of these play a crucial role in ensuring the safe and efficient operation of hydrogen fuel cell vehicles. They are designed to be durable, reliable, and efficient, allowing hydrogen fuel cell trucks to operate with minimal downtime and maintenance.

Related products:

- Seal-Lok™ Xtreme Tube Fittings

- O-Lok® / Seal-Lok™ H22/H2P Tube Fittings

- Two Ferrule Tube Fittings A-LOK®

- Single Ferrule Tube Fittings CPI™

- Pressure Sensor SCP04

- Parker Grade Tube for A-LOK®, CPI™, MPI™, Autoclave, O-Lok® and Seal-Lok™ Tube Fittings

- Ball Valves, Trunnion Style, HB Series

- Ball Valves B Series

- Medium Pressure Fittings Parker Autoclave

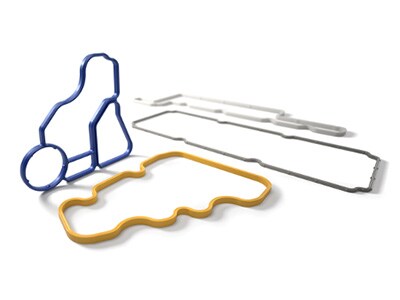

SEALING TECHNOLOGY FOR HYDROGEN FUEL CELLS

The use of sealing technology for hydrogen fuel cells

The fuel cell is a compact and powerful energy converter that converts chemical energy directly into electric (propulsion) energy by means of cold combustion, for instance on board of vehicles. Sealing of the individual components of the fuel cell stack and the supply and discharge lines of the fuel cell requires reliable sealing systems.

Featured sealing solutions

Sealing solutions from Parker Prädifa are found between the bipolar plates of fuel cells, in threaded connections of pipelines, valves, compressors, and nearly all other required components. These seals excel in terms of their wide temperature range, permeation resistance, mechanical robustness, and scalability to large volumes in mass production. Thermal interface material from Parker Lord and Parker Chomerics complement the offering.

Related products:

- Seals for Bipolar Plates

- CliPHvent Pressure Relief Valve

- Dynamic Seals (e.g. C1 Rod Seal)

- Press-in-Place Seals

- Warp Seals

- EPDM O-Ring (E8556)

- Chlorine-Butyl O-Ring (B8885)

- Polyurethane O-Rings V1 (P5009)

- Metal E-Seals

- Metal C-Seals

- PTFE Slipper Seals

- FlexiSeals®

- Composite Sealing Washers

- Thermal Interface Materials

- EMI Shielding Gaskets

ETHYLENE PROPYLENE RUBBER O-RING, 70 SHORE A, AUTOMOTIVE APPLICATIONS (PRÄDIFA SERIES E8556-70)

EPDM O-ring with focus on automotive, chemical processing, pharmaceutical and general industrial applications, black.

CHLORINE-BUTYL RUBBER O-RING , 70 SHORE A, GENERAL INDUSTRIAL APPLICATIONS (PRÄDIFA SERIES B8885-70)

CIIR O-Ring with focus on heating ventilation air conditioning (HVAC) and refrigeration, consumer, general industrial and hydrogen applications, black.

POLYURETHANE O-RING, BROAD APPLICABILITY (PRÄDIFA SERIES V1, ULTRATHAN®)

TPU O-ring with high wear and extrusion resistance, for high-pressure applications and small housings with no space for back-up rings, green.

PRESS-IN-PLACE ENCLOSURE SEALS

Parker’s Press-In-Place seals are custom designed seals that fit into complex groove patterns without having to be stretched or retained. These custom seals are designed to withstand a wide variety of environments, fluids, pressures and temperatures.

FLEXISEAL® PISTON SEAL

Flange seal. Internal pressure. Static and intermittently dynamic. FlexiSeal. Spring-energized PTFE seal. Low assembly force.

C-RING METAL SEAL

Metal C-Rings are flange seals for applications involving extreme temperatures, pressures or media. C-Seals are also suitable for use with uneven flanges.

E-RING METAL SEAL

Metal E-Rings (E-Seals) are flange/casing seals. They are designed for aerospace and general industrial high-temperature applications where the sealing gap enlarges due to operating pressure and thermal influences.

WARP SEALS

Warp Seals are special static seals that compensate for axial, radial and/or angular misalignment within a wide tolerance range. They are suitable, for example, for sealing port connections and feedthroughs of all kinds in housings.

VIBRATION ISOLATORS AND FLEXIBLE COUPLINGS

Vibration isolators are essential components in minimizing the transmission of energy from vibrating industrial and off-highway equipment to its surroundings. By effectively reducing noise and structural vibrations, these devices play a critical role in enhancing operational efficiency and comfort.

Vibration isolators work by decoupling the source of vibration from the environment, either by diminishing the amplitude of vibration or by shifting the resonance frequency away from operational frequencies.